As a general rule, instruments available on the

market give quick results. However, the type of instrument

used, the system accuracy, and the measurement protocol can

affect the reproducibility of the measurement. The ISO

13320-part1 standard has been developed in order to

provide the user with results that are independent of the

instrument used.

The standard requires that the manufacturer

calibrate the instrument using Certified Reference Materials

(CRMs) of a known size distribution. The user must also verify

operation of the instrument, both repeatability and accuracy,

at regular time intervals using CRMs. The main requirements of

the standard are the following:

Table 1: Summary of the main

requirements of the ISO 13320 standard.

|

Requirement |

Target values

|

Test

Method |

|

Repeatability

(6.4 in the standard)

|

Coefficient of

variation

<3% for X50

<5% for X10 & X90

(below 10Ám, these

values

should be doubled) |

The

measurement is done

on at least 5 different samples

from the same batch

|

|

Accuracy

(6.5 in the standard)

|

Maximum deviation from the certified range

:

<3% for X50

<5% for X10 &

X90

(below 10Ám,

these values

should be doubled)

|

Mean

value over

3 independent

measurements

|

Note: X50 represents

the median diameter in mm, which means 50% (by volume) of the

particles are smaller than this diameter.

The ISO13320-1 norm can be downloaded on the

ISO web site : click here

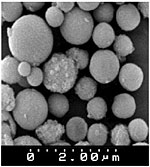

Certified Reference

Materials (CRMs) are made of spherical particles and the size

distribution of these particles must retraced to a recognised

size standard.

Certified Reference

Materials (CRMs) are made of spherical particles and the size

distribution of these particles must retraced to a recognised

size standard.

Fig 1. SEM Picture of Certified

Glass Beads (from Whitehouse Scientific)

Data collected using

the Cilas 930L,1064L and 1180L instruments showed better

repeatability and accuracy

values than required in the ISO 13320 standard. Statistics

from over 50 production instruments have shown a

reproducibility of better than 1%.

Fig 3. Measurement of the

10-100 m m CRM with a Cilas 1064 system

Fig 3. Measurement of the

10-100 m m CRM with a Cilas 1064 system

Cilas instruments are very

accurate because of their unique short bench design. All Cilas

systems use a permanently aligned optical bench without any

moving parts to provide superior repeatability.

The ISO 13320 standard provides the industrial

laboratory an effective method for instrument selection.

Laboratories who use the standard can guarantee the accuracy

and reproducibility of their measurements throughout the

entire life of the instrument.